Professional Supply CNC Flexible Nylon Gear Rack and Pinion Transmission Mc Nylon Gear Rack

Basic Info

| Type | Bevel Gear |

| Raw Material | PP, PE, HDPE, PTFE, PA, Mc Nylon, POM, etc. |

| Color | Customized Colors |

| Drawing Format | CAD / Pdf/ Dwg/ Igs/ Step/X-T etc. |

| Transport Package | Plastic Bag + Cardboard Box + Wooden |

| Specification | Customized size |

| Trademark | hongyue |

| Origin | China |

| Production Capacity | 50000000 PCS / Year |

Product Description

| Name | Nylon Gear |

| Material | Nylon,PEEK,PI,PEI,PU,PA,POM,PE,UPE,PTFE,etc. |

| Color | White, black, green, nature, blue, yellow, etc. |

| Condition | In stock/ Made to order |

| Shape | As per your drawing |

| Physical Properties | Physical Properties of Common Engineering Plastics |

| Other Shape | Sheet, rod, tube, gear, rack, pulley, guide rail, plastics fittings, and so on |

| Packing | Plastic bags, Cartons, Wooden case, Pallet, Container, etc. |

| Other | Shipping status notification during delivery.Regular notification of new styles & hot selling styles. |

| Feature: | Good abrasion resistance |

| Application | Industry, medical and pharmaceutical, semiconductor, photovoltaicenergy, chemical electronics, communications and other industries. |

Technological process:

1. Raw material preparation2. Audit and design drawings3. Processing products4. Quality inspection5. Repair product burr and inventory6. PackingOur Advantages1. We are factory providing CNC service and machining plastic parts2. Handling components of very tight tolerance and very complex geometry3. Low MOQ (1pc is even acceptable in some special conditions)4. Offering free and quick prototyping ( normally 1 week)5. Sharp on time delivery6. Top quality guaranteed by skilled workers, managing system and status of facilities.7. Offering consultancy service on components machining8. Customized size and spec /OEM available9. Near Beijing and Tianjing,Qingdao, convenient transportation.10, Our custom service for more than 20 years of experienceBetter services 1.QC System: 100% inspection on critical dimensions before shipment.2.Drawing format: CAD / PDF/ DWG/ IGS/ STEP/X-T etc.3.Packaging: Standardpackage / Pallet or container / As per customized specifications4.Payment Terms: 30 -50%T/T or Paypal/ Western Union in advance, 70-50% balance before delivery; PayPal or Western Union or T/T is acceptable.5.Shipment Terms: 1) 0-100kg: express&air freight priority, 2) >100kg: sea freight priority, 3) As per customized specifications6.Trade terms: EXW, FOB, CIF perfered

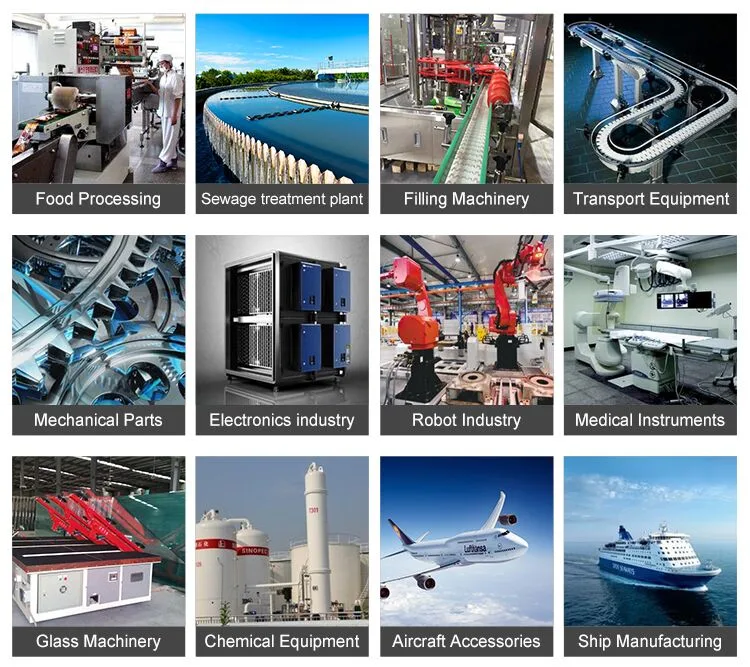

Application Areas

Packing Details : Inner plastic bag,outside carton box,last is the pallet,all are based on the customers' requirmentsDelivery Details : 10-30 days after you confirm the samplesPayment terms: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.If you have another question, pls feel free to contact us.

FAQ1.

Q: Are you trading company or manufacturer ?

A: We are manufacturer.2.

Q: How long is your delivery time?

A: According to the difficulty and quantity of product processing,a reasonable arrival time will be given to you.Usually 2-5 days for CNC machine processing parts. It will take around 2-4 weeks for mold making.3.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.4.

Q: Can you do assembly and customized package for us?

A: We have an assembly factory and can assemble all kinds of plastic, metal and electronic parts for you. For the finishedproducts,we can customized the retail package and you can sell it directly after receiving them.