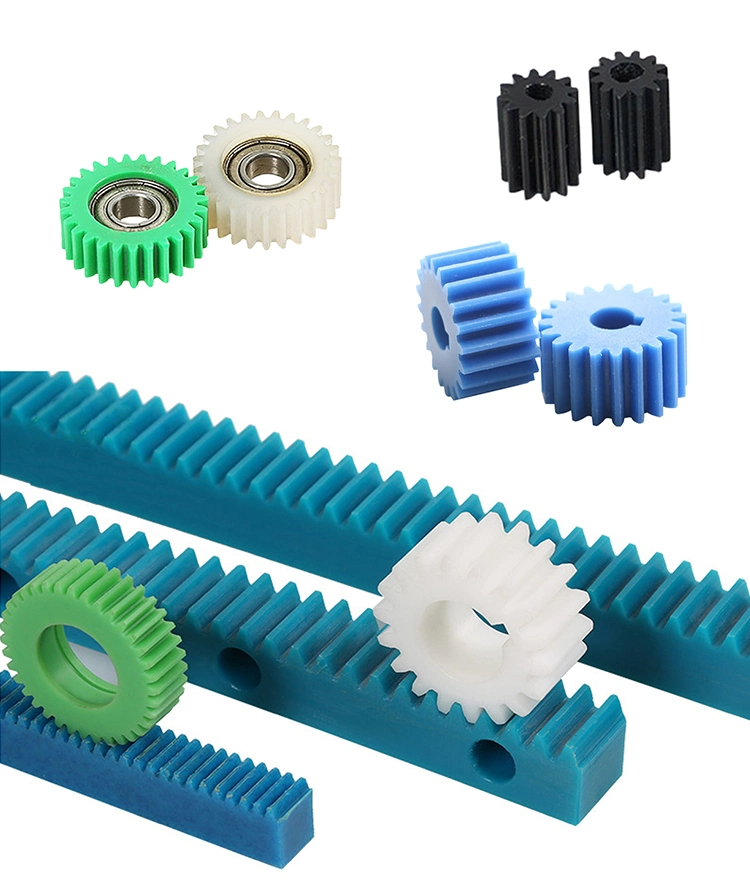

Sliding Gate Plastic POM Gear Rack

custom spur cnc plastic nylon pom flexible gear rack and pinion for linear motion Guangdong Enginnering Plastics Industr

Basic Info

| Model NO. | pom gear rack |

| Certificate | ISO9001: 2008, Test Report, RoHS |

| Service | 24 Hours Online |

| Feature | High Precision;Free Design;OEM&ODM |

| Sample | Available |

| Quality Control | 100% Inspection |

| Desity | 1.6g/cm3 |

| Shape | Sheet ,Rod,Gears Chain and So on |

| Size | Customized |

| Transport Package | Paking in Cartons,Wooden Case,Pallet,Container,Ect |

| Specification | Customized |

| Trademark | Engineering plastics |

| Origin | Made in China Guangzhou |

| HS Code | 3926909090 |

| Production Capacity | 100000/Month |

Product Description

Guangdong Enginnering Plastics Industries (Group) co., Ltd established in January 2009 , is a professional production

of "engineering plastics accessories" high-tech enterprises. Company main products : UHMW-PE , MC Nylon , PA6 ,

POM, HDPE , ABS , PU , PC , PVC, PP , PET , PBT , Acrylic, PEEK, PTFE , PVDF , PAI, PEI , PSU , PI, PBI

Antistatic product series . Company also provide wide range of accessories processing conditions , such as mass

customization production ability , exquisitemanufacturing technology and advanced production equipment , professional

technical advice and after-sales service. Companies strictly enforce the ISO9001(2008) International quality certification

system , the product quality conforms to the EU Rohs standard .

| Name | Plastic nylon6 sleeve |

| Material | High Performance Engineering Plastics--100% Virgin Nylon6 Raw Material. |

| Color | Nature color / Customized |

| Advantage | 1.Very good sliding properties even without lubrication 2.Good thermal mechanical bearing strength 3.Good chemical and hydrolysis resistance even against superheated steam 4.Very wear resistant 5.Very rigid 6.Light weight |

| Brand Name | Engineering Plastics / OEM |

| Size | Custom made as your drawing or sample |

| Density | 1.2g/cm3 |

| Manufacture way | Molding Injection and CNC Machinery process |

| MOQ | Accept the Sample order, and supply good price for the big quantity order. |

| Certification | ISO9001,SGS,FDA,RoHS,Test Report,ect. |

| Sample | Free the molding injection sample for customers after paying the mould Cost. |

| Sample time | 30 Days for manufacturing the injection mould and finished the samples for Customers. |

| Mass production time | 10-30 days based on the order quantity. |

| Payment | PayPal, Escrow, Western union, Money Gram, T/T and Alibaba Trade Assurance. |

| Packing | 5-ply environment-friendly corrugated boxes/ Plastic Pallets/ Wooden Pallets/ wooden cartons/ 20 feet Container / 40feet Container/ Customized |

| Other | 24 hours instant and comfortable customer service. Shipping status notification during delivery. Regular notification of new styles & hot selling styles |

2, high strength steel hardness HRC28, phosphoric acid plating on the surface and after lubrication

Each lock nut is provided with independent packaging to ensure quality

imported production equipment and CNC processing equipment, processing means advanced, strong technical force.

other countries are visitingQ1. We don't have drawings, can we produce according to the samples we provide?

A1. OK

Q2. How to customize plastic parts?

A2. Customized according to drawings

Q3. Can I make a sample for testing first?

A3. OK

Q4. How long is the proofing cycle?

A4. 2-5 days

Q5. What are your processing equipment?

A5. CNC machining center, CNC lathe, milling machine, engraving machine,injection molding machine, extruder, moldin

machine

Q6. What craftsmanship do you have for processing accessories?

A6. According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. OK. Surface treatment: spray paint, silk screen, electroplating, etc.

Q8. Can you help assembling the product after it is made?

A8. OK.

Q9. How much temperature can the plastic material withstand?

A9. Different plastic materials have different temperature resistance, the lowest temperature is -40ºC, and the highest

temperature is 300ºC. We can recommend materials according to the working conditions of your company.

Q10. What certifications or qualifications does your company have?

A10. Our company's certificates are: ISO, Rohs, product patent certificates, etc.

Q11. How scale is your company?

A11. Our company covers an area of 2,000 square meters and has 100 employees.

Send to us